COVID-19 has disrupted global supply chains, but business fundamentals haven’t changed. Your company still needs electronic interconnects at competitive prices. You also need vendors who can meet delivery dates and quality standards. Over time, your business will continue to validate new suppliers and work to mitigate risk. These are basic business functions, but are you ready to perform them in a way that accounts for the supply chain lessons of COVID-19?

If you’re interested in supply chain resilience, Willy C. Shih’s recent article in the Harvard Business Review is essential reading. Shih, a professor of management practice in business administration at Harvard Business School, examines global supply chains in our post-pandemic world and describes three ways you can uncover and address hidden risks.

- Identify your vulnerabilities

- Diversify your supply base

- Hold intermediate inventory or safety stock

Let’s take a look at each in terms of how you buy electronic interconnects.

Identify Your Vulnerabilities

Many companies limit their risk assessments to large suppliers. They also ignore the risks associated with transportation and distribution. As COVID-19 revealed, however, a thorough review of your supply chain is in order. By comprehensively reviewing all of your suppliers and categorizing them as low, medium, or high risk, you can plan for future disruptions. Remember, too, that long supply chains carry greater risk and that the lowest prices can carry hidden costs.

Diversify Your Supply Base

Excessive dependence is risky, whether it’s with a single supplier or a single part of the world. As Shih recommends in his article for Harvard Business Review, “Managers should consider a regional strategy of producing a substantial proportion of key goods within the region where they are consumed.” For example, if you need electronic interconnects for products that are sold in North America, there are cost-effective alternatives to Asia.

Hold Intermediate Inventory or Safety Stock

Just-in-time inventory (JIT) isn’t dead, but the shortages associated with COVID-19 reminded managers that there can be bigger problems than tying-up cash in inventory. Businesses need to run lean but while maintaining adequate safety stock. Otherwise, you risk paying too much or being forced to shut-down product assembly. By partnering with SHINE, you can relieve the burden of component sourcing and strengthen your overall operations.

SHINE’s support for Kanban programs also shows how we support you. By working with our customers’ pull systems to optimize the flow of resources, we replace only what has been consumed and analyze actual demand and consumption rather than following generic forecasting. Our Kanban boards also provide our production personnel with powerful visualization tools that help to optimize workflow.

How SHINE Helps You to Reduce Supply Chain Risk

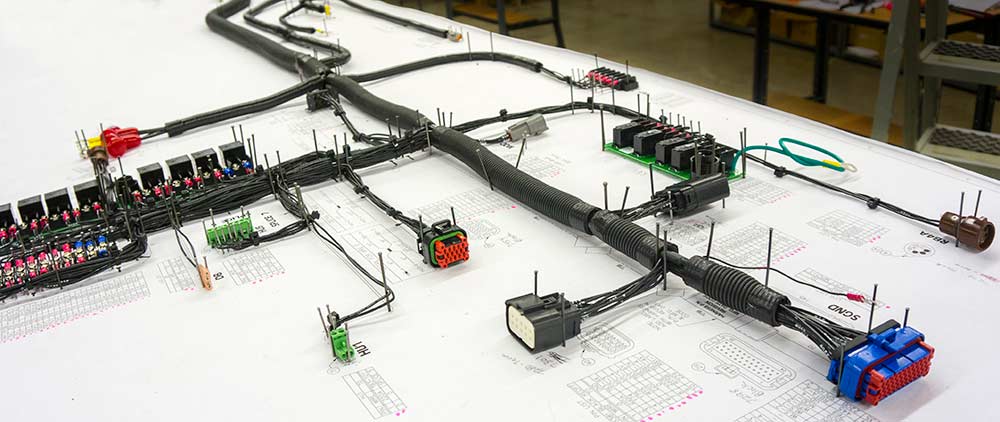

SHINE manufactures custom cable assemblies, electro-mechanical assemblies, and wire harnesses that can strengthen your supply chain. With our unique blend of engineering resources, account management, and an approved global supply chain, we are a reliable and cost-effective extensive extension to your manufacturing operations. Whether you’re looking for a primary supplier of electronic interconnects or a second source, we invite you to contact us.